|

|

|

| ROLLER CODERS |

HOME > EQUIPMENT > ROLLER CODERS > MARSH ROLLER CODERS |

||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

|

ROLLER CODERS |

|||||||||||||||||||||||||||||||

|

Conveyor Line Printers (CLPs) automatically print data on moving cartons and other flat surfaced materials with unsurpassed accuracy and legibility. These machines are mounted tight on the conveyor line and require no power or operator assistance to print high quality impressions thousands of times a day. |

|||||||||||||||||||||||||||||||

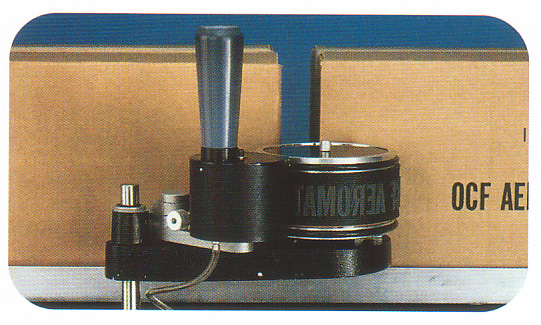

^ Non Porous CLP with optional 4oz. ink reservoir cartridge. |

Non- porous Conveyor Line Printers

The non porous

conveyor line printer provides the ultimate in low maintenance printing

on all types of non porous materials. Unmatched in quality and

performance, these printers have completely eliminated the problems

associated with the use of fast drying inks. |

||||||||||||||||||||||||||||||

|

The revolutionary design of the

patented non porous inking system prevents solvent evaporation from the

ink roll and enables the use of inks that dry as fast as 2 seconds at 75

degree Fahrenheit ambient temperatures. |

|||||||||||||||||||||||||||||||

| Features include precision machined aircraft aluminum housings, stainless steel columns and shaft and sealed ball bearings in both the print drum and anilox roll. Mounting brackets and ribtype print drums are standard equipment. |

|

||||||||||||||||||||||||||||||

|

Porous CLP

< Porous CLP with optional 4 oz. reservoir ink cartridge and roller cover. |

||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

Marking Method Systems (S'pore) Tel: +65 6-250-3500 / Fax: +65 6-250-7083